OUR 35TH ANNIVERSARY STORY

The role NCB Hazcheck (Exis Technologies) has played in shipping dangerous goods over the past 35 years and future plans for Safety of Life and Cargo at Sea

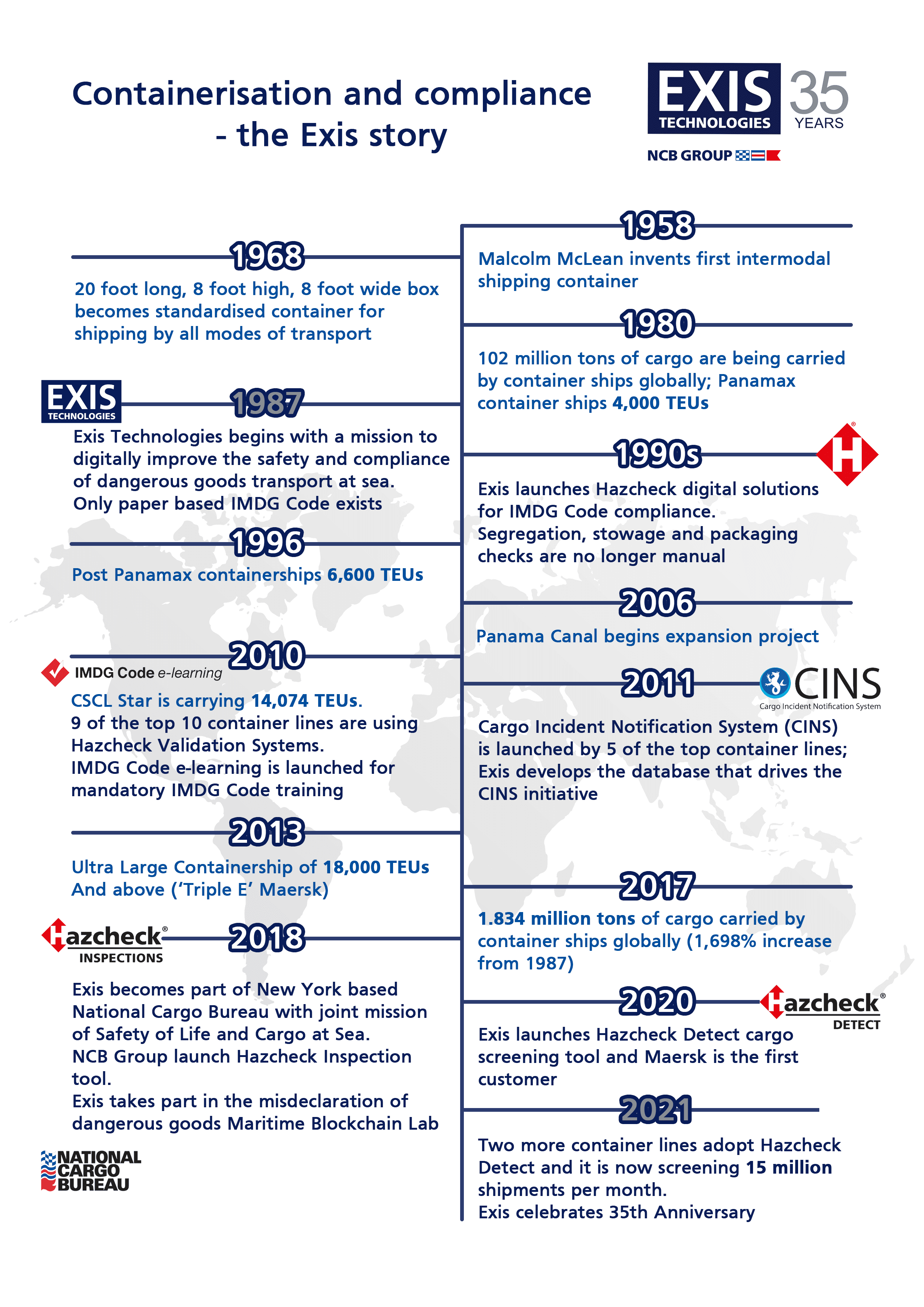

The Evolution of Containerization in Shipping

In 1956, when the roots of containerization were planted, American entrepreneur Malcom McLean took the lead in seeking a swift and efficient method to load his trucking company’s entire cargo onto shipping vessels. Little could he have foreseen that, by 2022, container shipping would be responsible for transporting around 90% of non-bulk cargo. Over the ensuing decades, this ground-breaking concept reshaped global trade, spurred advancements in logistics technology. Consequently, the initial challenges faced by McLean led to a flourishing industry shaping international commerce. Through this transformative journey, containerization seamlessly wove into modern trade, propelling efficiency and global connectivity. Approximately 10% of this containerised volume constitutes recognized Dangerous Goods.

NCB Hazcheck: 35 Years of Innovation in Dangerous Goods Management

In 2022, NCB Hazcheck celebrated 35 years supplying IT solutions for managing dangerous goods in sea transport. Hazcheck Systems help shippers, consignors, forwarders, and shipping lines in complying with regulatory requirements for shipping containerized dangerous goods by sea. Earlier methods were paper-based, time-consuming, and relied on many people in the process understanding the cargo and its handling requirements. Getting the answers wrong to important questions like; Which goods are actually classified as dangerous goods? Can they be shipped together safely in a container? What packaging do they need? and Where should they be stowed in the ship? The consequences of answering these questions wrong could be catastrophic.

In 1987, the IMDG Code, produced by the International Maritime Organization, only existed in book format. Widespread use of digital solutions was not prevalent in the shipping industry at the time. Programmers at NCB Hazcheck took the initiative to develop the first digital dangerous goods list database. They also created basic lookup tools for international multimodal regulations, significantly expediting the booking process.

Moving into the 1990s, NCB Hazcheck independently crafted digital solutions capable of swiftly identifying correct UN numbers or proper shipping names. These solutions not only facilitated packaging but also conducted segregation and stowage checks, producing documentation integral to the transport chain. NCB Hazcheck actively pursued innovation. By 2010, the top 10 container lines had implemented Hazcheck Validation Systems, showcasing the company’s commitment to cutting-edge solutions. Concurrently, NCB Hazcheck proactively launched its IMDG Code e-learning training tool, aligning with the IMO’s new mandatory IMDG Code training guidelines. This proactive approach marked NCB Hazcheck as a pioneer in developing and implementing solutions that actively enhanced safety and efficiency within the shipping industry.

The Impact of Digital Solutions on Container Shipping Evolution

Digital solutions produced by NCB Hazcheck have allowed the businesses to keep pace with the advancement of container shipping today. In 1987, NCB Hazcheck took shape, and back then, the Panama Canal constrained the size of the largest container ships, capping their capacity at about 4,600 TEU. Fast forward to today, and Ultra Large Container Ships, boasting a staggering capacity of nearly 24,000 TEU, are a common sight in container ports. The transformation is striking—container shipping has evolved immensely. In 1980, global container ship cargo reached 102 million tons, a pivotal moment in the industry’s history. By 2017, the figure surged to 1.834 million tons (source UNCTAD, Clarkson Research Services copyright Statista 2019), marking a massive 1,698% increase!

In the past 35 years, containerization in shipping has undergone a remarkable evolution, influencing vessel sizes and port infrastructure development. This transformation has continuously shaped global road and rail networks.

Beginning in 1968, the creation of the standard 20-foot container box transformed the shipping industry actively. Its effects extend beyond container ships, including the redesign of ports, optimization of road and rail networks. The broader influence on cities and countries globally is profound, shaping the landscape of international trade and logistics. The ongoing evolution of containerization is a dynamic force, shaping how goods are transported and influencing global trade. This innovation sparked a revolution, reshaping landscapes and infrastructures as it influenced various sectors globally.

Collaborations and new initiatives

NCB Hazcheck does not stand still, actively seeking collaborations and driving initiatives for continuous safety improvements in containerization. In 2011, the Cargo Incident Notification System (CINS) launched as a major industry collaboration, bringing together five top container lines. The primary goal was to analyze global operational information regarding all cargo and container-related accidents.

Celebrating its 10th anniversary in 2021, CINS boasts 17 shipping line members, representing over 85% of the world’s container slot capacity. NCB Hazcheck, now a CINS board member, has played a crucial role in the development of the CINS net database. This database propels the CINS initiative forward, contributing significantly to enhanced safety measures in container shipping. Furthermore, NCB Hazcheck actively participated in shaping new safety standards for the stowage of Dangerous Goods (DG) on board containerships. This collaborative effort, initiated by CINS in response to the Maersk Honam fire, involved NCB Hazcheck as a working group member. Their focus was on leveraging their extensive knowledge of the IMDG Code Dangerous Goods List, stowage requirements, and categorizing specific UN numbers into risk zones. As a result, Hazcheck Risk Zone data, comprising UN number, packing group, and risk zones, is now accessible as a free resource for the container shipping industry.

Tools and Solutions for Dangerous Goods Management

In 2018, NCB Hazcheck joined New York-based National Cargo Bureau, both sharing a mission for Safety of Life and Cargo at Sea. NCB’s Dangerous Goods White Paper, launched in 2020, emphasizes the industry’s need to collaborate for a robust approach to dangerous goods shipping.

The TT Club, a leading insurance provider in transport and logistics, notes that containerships, on average, face a major fire every 60 days. The intentional incorrect declaration of cargo, aimed at cutting costs or saving time, worsens this alarming frequency. Larger vessels face the brunt of these incidents. With approximately 60 million packed containers moved annually, a substantial 10 percent declare dangerous goods, contributing to the extensive scale of the issue. This situation poses a considerable risk to the safety and security of maritime operations. It emphasizes the urgent need for proactive measures to address and mitigate the challenges associated with misdeclaration and the transport of dangerous goods. Some ships may carry more than 1,000 containers with dangerous goods on any given voyage.

NCB and NCB Hazcheck have been developing ground-breaking tools for 4 years, addressing containerization challenges. Hazcheck Detect, an API-based cargo screening solution launched in 2020, is already operational with major container lines, including Maersk. The system scans booking details actively, pinpointing potential misdeclarations and undeclared dangerous goods (DG) by creating an industry library using keywords. Cargo screening ensures the quick detection of non-compliant cargo within seconds, a significant improvement over the previous days-long process. Real-time monitoring allows for the instant identification of last-minute changes to bookings, declarations, Bills of Lading, and shipping instructions. This proactive approach prevents such cargo from being loaded onto a ship, effectively mitigating the risk of fires at sea.

New technologies and the importance of data

As the shipment of dangerous goods is complex, Blockchain could enhance safety in the maritime sector. A key proposition for using Blockchain is digital traceability of DG through the supply chain, boosting security and transparency. In 2018, NCB Hazcheck participated in the misdeclaration of dangerous goods blockchain project, Maritime Blockchain Labs. The initiative was led by Bloc with the support of Lloyd’s Register Foundation.

Players in the supply chain must actively address remaining challenges associated with Blockchain. The key lies in the willingness and ability of these participants to share their data. In the future, this shared data is poised to play a pivotal role in significantly contributing to enhancing the safety of containerized shipments. Furthermore, the potential impact extends beyond safety measures to include the digitization of various dangerous goods (DG) documentation. This encompasses the automation of transmission and updating of DG information, revolutionizing the entire landscape of containerized shipping practices. It is essential for stakeholders to take proactive steps, fostering collaboration and embracing the transformative capabilities of Blockchain technology. Active engagement and leveraging shared data empower the supply chain to unleash Blockchain’s full potential. This transformation enhances the handling of DG documentation, ensuring a safer and more efficient containerized shipping process.

Data-Driven Hazcheck Solutions and Future Developments

We are now able to collect large amounts of data from all of our Hazcheck tools. “In the year 2021, utilizing our Hazcheck tools for declared dangerous goods, we conducted over 400,000 validations per month, accounting for 82% of the world’s DG/hazmat container traffic. Additionally, we identified and rejected approximately 4,000 shipments each month. The Hazcheck Inspections used by NCB in their container inspection database has an excess of 100,000 data records and is constantly growing. Hazcheck Detect actively screens over 15 million shipments monthly. Leveraging machine learning and AI techniques, these data sets enhance the detection of invalid and dangerous shipments. Anticipating the year 2022, we expect to deliver additional advancements in our industry solutions. This is particularly crucial, given the dynamic nature of containerization, ensuring ongoing innovation and continual improvement in our capabilities. Furthermore, these developments are vital for staying at the forefront of the evolving industry landscape.